CNC turning and milling parts

NC turning and milling parts usually have the following advantages:

1 The NC iron bed is characterized by high flexibility, that is, it is flexible, universal and effective. It can process workpieces of different shapes. It can complete drilling, boring, hole calibration, plane milling, inclined plane milling, slot milling, curved surface milling (CAM), thread tapping and other processing on the NC milling machine. In general, the required processing procedures can be completed at one time

2. The machining accuracy is far from

now, the pulse equivalent of NC device is usually 0.001 mm, and the NC system with appropriate accuracy can reach 0.1 μ m. Usually, it can protect the accuracy of the workpiece. In addition, NC machining also avoids the operation errors of operators. The size identity of the same batch of machined parts is good, which improves the product quality to a great extent. Because the NC milling machine has high machining accuracy and can process many complex surfaces that are difficult or impossible to be processed by ordinary machine tools, it shows its advantages in processing all kinds of complex molds

3. Good production efficiency

NC milling machine usually does not use one-to-one fixture and other one-to-one process software. When replacing the workpiece, you only need to call the machining program stored in the NC device, clamp the workpiece and adjust the tool data, so it can shorten the production cycle. Secondly, CNC milling machine has the functions of milling machine, milling machine and milling machine, which makes the process highly concentrated Excellent, improve the production efficiency and reduce the workpiece clamping error. In addition, the spindle speed and feed speed of NC milling machine are stepless, so it is conducive to select good cutting parameters. The CNC milling machine has the functions of fast forward, fast backward, suitable speed and positioning, which can reduce the maneuvering time. According to statistics, the production efficiency of NC milling machine can be increased by 3 ~ 5 times compared with that of ordinary milling machine. For complex forming surface processing, the production efficiency can be increased by more than ten times or even dozens of times

in addition, the use of CNC milling machine can improve the working conditions of workers and reduce the labor intensity

machining center is developed from NC milling machine. The big difference from NC milling machine is that the machining center has the ability to automatically exchange machining tools. By installing tools for different purposes on the tool magazine, the machining tools on the spindle can be changed through the automatic tool change device in one clamping to realize a variety of machining functions

machining center is an efficient automatic machine tool composed of mechanical equipment and NC system, which is suitable for machining complex parts. The compilation of machining program is an important factor to determine the machining quality. The machining center is a CNC machine tool. The workpiece can complete the processing of multiple processes in one clamping. At the same time, it is also equipped with a tool library and an automatic tool change function. These rich functions of machining center determine the complexity of machining center programming

the form of multi process centralized machining has been extended to other types of NC machine tools, such as turning center. It is equipped with multiple automatic tool changing devices on the NC lathe, which can control more than three coordinates. In addition to turning, the spindle can stop or index, and the milling, drilling, reaming and tapping processes are carried out by tool rotation, which is suitable for machining complex rotating parts

the machining center can realize the linkage control of three or more axes to protect the tool for machining complex surfaces. In addition to the functions of linear interpolation and circular interpolation, the machining center also has the functions of various machining fixed cycles, automatic compensation of tool radius, automatic compensation of tool length, graphic display of machining process, man-machine dialogue, automatic fault diagnosis, off-line programming and so on

the same as the NC milling machine, the machining center is also composed of computer numerical control system (CNC), servo system, mechanical body, hydraulic system and other parts. However, the machining center is not equal to the NC milling machine. The big difference between the machining center and the NC milling machine is that the machining center has the function of automatic tool exchange. By installing tools for different purposes in the tool library, the machining tools on the spindle can be changed through the automatic tool exchange device in one clamping to realize various machining functions such as drilling, boring, reaming, tapping, grooving and so on

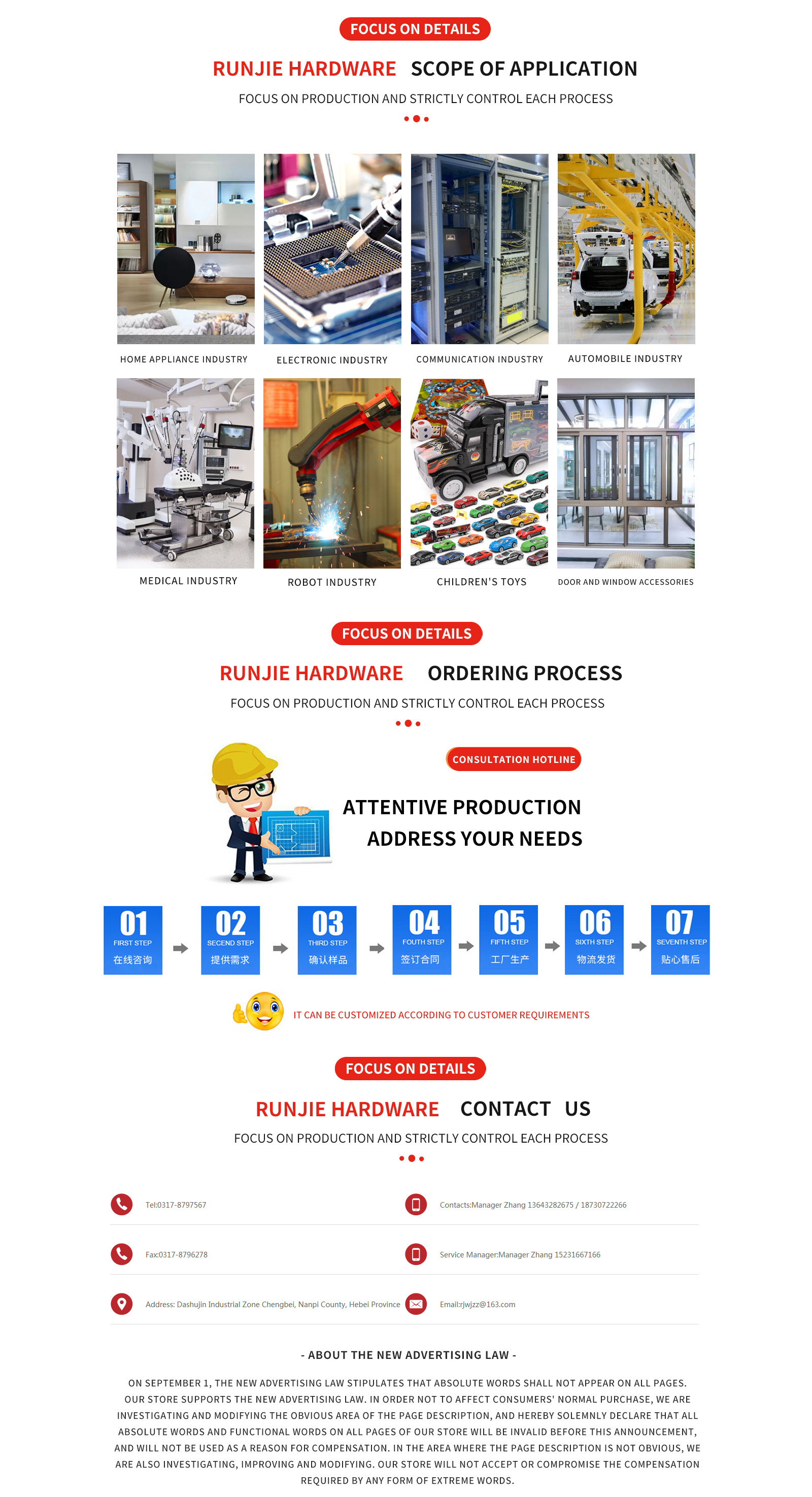

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1