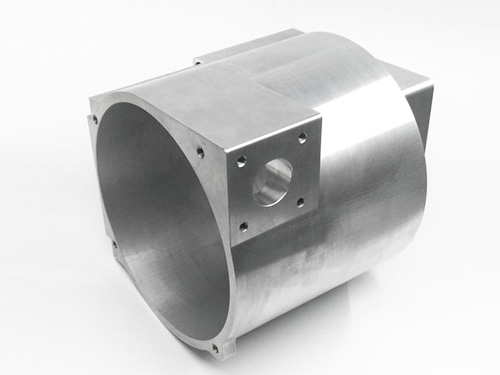

Machining of aluminum parts

There are many materials of products processed by CNC machine tools, among which aluminum parts are one of the most processed. When machining aluminum parts with CNC machine tools, we should pay attention to these places if we want to stabilize the machining size

1. Status of machine tool. Whether the processing is stable or not largely depends on the state of the machine tool itself. Before processing, we should check the machine tool itself and start the equipment after there is no problem

2. Material cooling. The workpiece may be deformed after cooling. This situation is often difficult to avoid. At this time, special attention should be paid to the use of coolant. The possibility of material deformation should also be considered during in-situ measurement

3. Processing technology. Unreasonable processing technology is easy to cause dimensional error of workpiece. On the basis of protecting the basic processing technology (such as "rough before fine, face before hole, large face before small face" in milling NC processing, or "reduce the number of clamping and try to use combined fixture" and other basic processing technology details in fixture use), the processing error caused by iron filings on aluminum parts shall be minimized

4. Parameter setting. Cutting speed, feed rate, cutting scale and tool compensation will affect the stability of machining, so special attention should be paid

5. Tool selection. When processing aluminum parts, try to use one-to-one tools, which are often more targeted. For example, the one-to-one milling cutter for milling aluminum usually has a larger rake angle and spiral angle, and the cutting edge is sharper, which is more conducive to the processing of aluminum parts (such as anti chip formation), and the processed surface quality will be excellent

6. Stress. Aluminum parts are made of soft materials, so special attention should be paid to the clamping strength. In addition, in the process of processing, the aluminum parts are opened in good condition and stand for a period of time before the next process is carried out to eliminate the stress

in addition, in the processing of aluminum parts, attention should also be paid to chip removal and the use of cutting fluid. There are many factors affecting the processing stability of aluminum parts, so we should deal with them flexibly and analyze the specific problems. Stable machine tools, reasonable processing technology and cutting tools, and the technical level of operators are all factors affecting product quality

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1