CNC machined parts

Generally, CNC machining parts usually refer to computer digital control machining, CNC machining lathe, CNC machining milling machine, CNC machining boring and milling machine, etc

CNC index control machine tool is programmed and controlled by NC machining language, usually G code. NC machining G code language tells the NC machine tool which Cartesian position coordinates to use, and controls the feed speed and spindle speed of the tool, as well as the functions of tool converter, coolant and so on

CNC machined parts have the following advantages:

① greatly reduce the number of tooling, and complex tooling is not required for machining parts with complex shape. If you want to change the shape and size of parts, you only need to modify the part processing program, which is suitable for new product development and modification

② stable processing quality, good processing accuracy and good repetition accuracy, which can meet the processing requirements of aircraft

③ in the case of multi variety and small batch production, the production efficiency is higher, which can reduce the time of production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of good cutting quantity

④ it can process complex surfaces that are difficult to be processed by conventional methods, and even process some processing parts that cannot be observed

What are the steps of CNC machining

1. Analyze the machining drawings and determine the machining process

according to the machining drawings provided by the customer, the technicians can analyze the shape, dimensional accuracy, surface roughness, workpiece material, blank type and heat treatment status of the parts, and then select the machine tool and cutting tool to determine the positioning clamping device, machining method, machining sequence and cutting amount. In the process of determining the machining process, we should fully consider the command function of the NC machine tool used, give full play to the efficiency of the machine tool, and achieve reasonable machining route, less tool walking times and short machining hours

2. Reasonably calculate the coordinate value of the tool path

calculate the motion path of the center of the tool path according to the geometric size of the machined parts and the set programming coordinate system, which is deeply influenced by all the tool position data. General CNC system has the functions of straight-line interpolation and circular arc interpolation. For the contour processing of plane parts with simple shape (such as parts composed of straight line and circular arc), it only needs to calculate the starting point and end point of geometric elements, the center of circular arc (or radius of circular arc), and the coordinate value of the intersection or tangent point of two geometric elements. If the NC system has no tool compensation function, the coordinate value of the motion path of the tool center shall be calculated. For parts with complex shapes (such as parts composed of non-circular curves and surfaces), it is necessary to use straight line segments (or arc segments) to approximate the actual curves or surfaces, and calculate the coordinate values of their nodes according to the required machining accuracy

3. Write the CNC machining program of parts

calculate the tool path data, determined process parameters and auxiliary actions according to the tool path of parts. Programmers can write the machining program of parts paragraph by paragraph according to the functional instructions and program segment format specified by the NC system. Attention should be paid to: good sales volume, standardized program writing, and easy expression and communication; Excellent, on the basis of being fully familiar with the performance and instructions of the NC machine tool used, the skills of using each instruction and programming segments

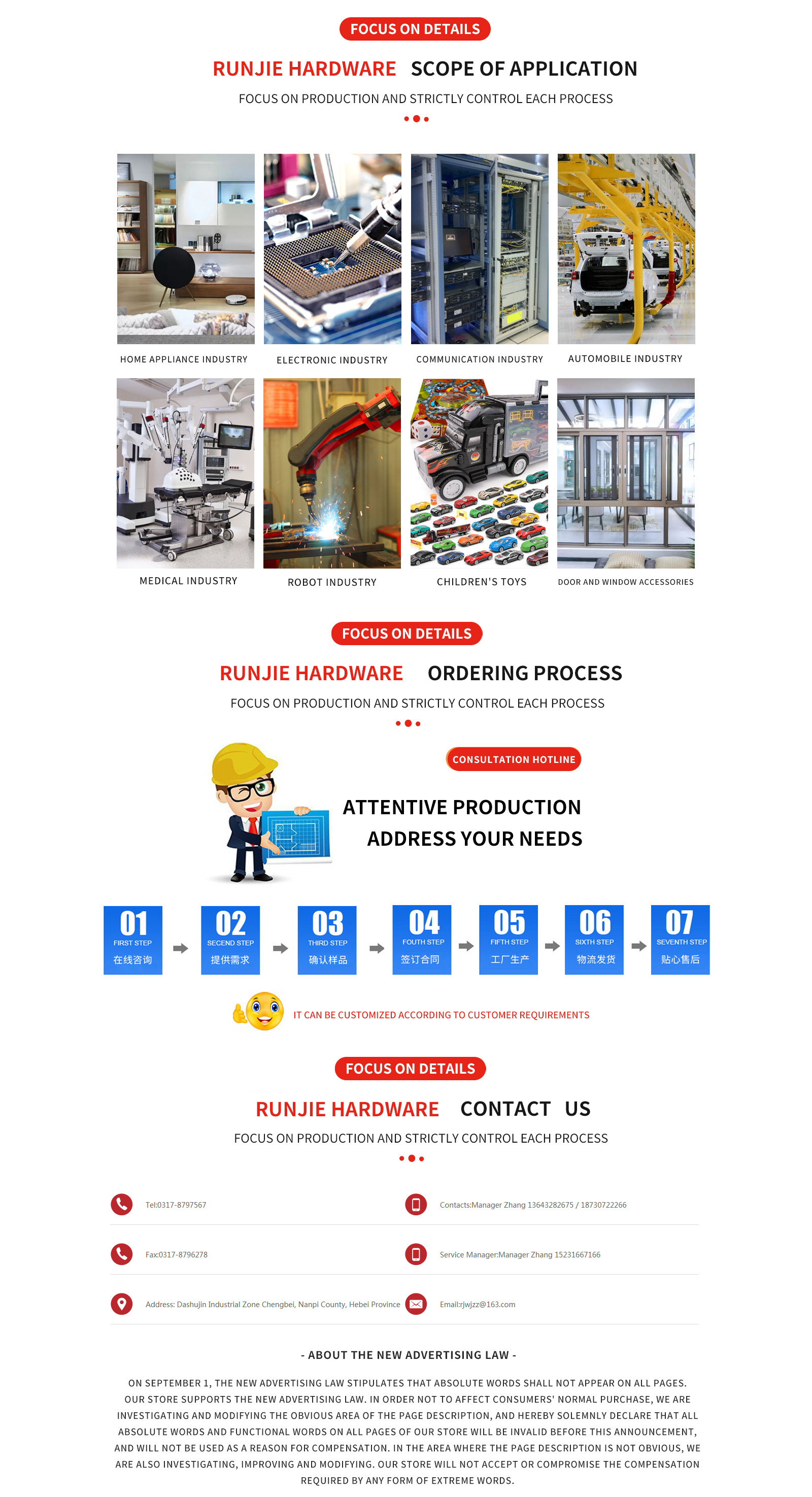

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1