Sheet metal cabinet

Sheet metal cabinet processing has seven main processes in the production process, which are basically: product design - cutting and blanking - drawing and setting out - blanking processing - bending processing - welding connection - overall assembly. In order to produce high-quality server cabinet, Yizhou cabinet has very strict requirements for each step

the sheet metal processing of equipment cabinet shell is generally made of cold-rolled steel plate or alloy, which is used to store the cabinet of computer, power or related electronic control equipment. The sheet metal cabinet can not only protect the stored related equipment, but also shield electromagnetic interference. Through reasonable planning, it is convenient for equipment installation and later management and maintenance

work task of sheet metal cabinet product design

the types of cabinet product design are different, and their procedures are also different. The main work task of cabinet design is to conduct experimental research on the product structure scheme of the new product, the parts constituting the whole machine, as well as the associated new principles and new technology, obtain the technical parameters required in the design, draw the structural sketch of the cabinet, and determine the detailed structure of each part of the new product Size and its matching relationship and technical conditions, calculate the strength and rigidity of structure and parts, conduct technical and economic analysis on cabinet products, and check whether its performance and cost meet the requirements of product equipment scheme

after the cabinet design is completed, it is necessary to organize relevant departments to review and improve the design of the product structure, manufacturability and operation performance. After passing the design, the cabinet products must be trial produced before mass production

the first process of sheet metal cabinet processing and production - shearing

the shearing equipment used in the cabinet industry is the gantry shearing machine. The gantry shearing machine is the most widely used shearing equipment. Its blade is long and can cut wide sheets. The shearing thickness depends on the power of the shearing machine. The gantry shearing machine is mainly used to cut straight lines

according to the position of the transmission mechanism, the gantry shear machine is divided into upper transmission and lower transmission

the transmission mechanism of the lower transmission gantry shearing machine is located at the lower part of the shearing machine, and its frame is light, but the area around the shearing machine is large. When the shearing thickness is thick, the power of the shearing machine will increase, and its transmission mechanism will be huge, which is inconvenient for work. Therefore, this kind of shearing machine is suitable for shearing plates with a thickness of less than 5mm

sheet metal cabinet processing parts stamping

stamping production mainly uses stamping equipment and dies to realize the processing process of metal materials. Therefore, the stamping process of sheet metal cabinet processing has the following characteristics:

1. Good productivity, simple operation, easy mechanization and automation, especially suitable for mass production

2. Stamping parts have smooth surface, stable dimensional accuracy, interchangeability and low cost

3. Parts with good strength, high stiffness and low weight can be obtained under the condition of low material consumption

4. Parts with complex shapes that are difficult or impossible to be processed by other processing methods

bending technology for processing workpieces in sheet metal cabinet

bending refers to that the metal sheet first undergoes elastic deformation under the pressure of the upper or lower die of the bending machine, and then enters plastic deformation. At the beginning of plastic bending, the sheet is free to bend. With the pressure of the upper die or the lower die on the plate, the plate is gradually close to the inner surface of the V-groove of the lower die. At the same time, the radius of curvature and bending force arm are also gradually reduced. Continue to pressurize until the stroke is terminated, so that the upper and lower dies are in full contact with the plate at three points. At this time, a V-bend is completed, which is commonly known as bending

the bending forming of workpieces processed by sheet metal cabinet is often carried out on mechanical press, friction press or hydraulic press. In addition, it is also carried out on one-to-one equipment such as bending machine, pipe bending machine and stretch bending machine. Bending on press is characterized by linear movement of tools, which is called bending; Bending forming on some one-to-one equipment, in which the tool rotates, is called bending or hydraulic pressure

welding process in sheet metal cabinet processing and production

1 The welding seam of the cabinet shall be neat and uniform, and there shall be no crack, undercut, notch, burn through and other defects. There shall be no slag inclusion, air hole, weld bead, pit and other defects on the outer surface and no obvious on the inner surface

2. The welding shall be firm and excellent, and the solder on the outer surface of parts shall be in place and filled without gap

3. Welding slag and arc are not allowed to damage other non welding parts of parts and components, especially the visible parts outside. The welding slag after welding shall be removed, including the removal of various particles adhered to the surface of parts by solder spatter

4. The surface of parts and components shall be ground and polished after welding, and the surface roughness value is 12.5. For some welding surfaces in the same plane, there shall be no visible bulges and depressions on the surface after treatment

5. The welding process shall be formulated to eliminate the welding stress as much as possible. Tooling shall be provided during welding, and various deformation of parts due to welding is not allowed. The workpiece shall be corrected after welding if necessary

sheet metal cabinet processing surface treatment process

1. Degreasing and derusting: in order to obtain a good coating, it is a very key step to remove the grease and sundries on the cabinet surface. Usually, the oil dirt on the product surface is removed by the dissolving and saponification of useful solvents. There are manual rust removal and chemical rust removal. Manual rust removal is to use abrasive cloth and steel wire brush to rub on the surface of the workpiece of the chassis and cabinet to remove rust. Chemical rust removal is to use the chemical reaction between acid solution and metal oxide to dissolve it in acid solution to achieve the purpose of rust removal

2. Phosphating: phosphating refers to the use of chemicals to clean the metal surface and form a stable phosphate protective layer to isolate the air and prevent the surface oxidation of the cabinet

3. Powder spraying: the coating is small solid particles, which can reduce environmental pollution. When the powder is injected into the coating nozzle by the electrostatic force, the more the powder is absorbed by the coating nozzle, and the more the powder is absorbed by the electrostatic force, so that the powder will continue to form a uniform flow through the coating nozzle. When it is sprayed by the electrostatic force, the more the powder will be absorbed by the coating nozzle, and then the powder will be formed by the electrostatic force After curing, a hard film is formed on the surface of the cabinet

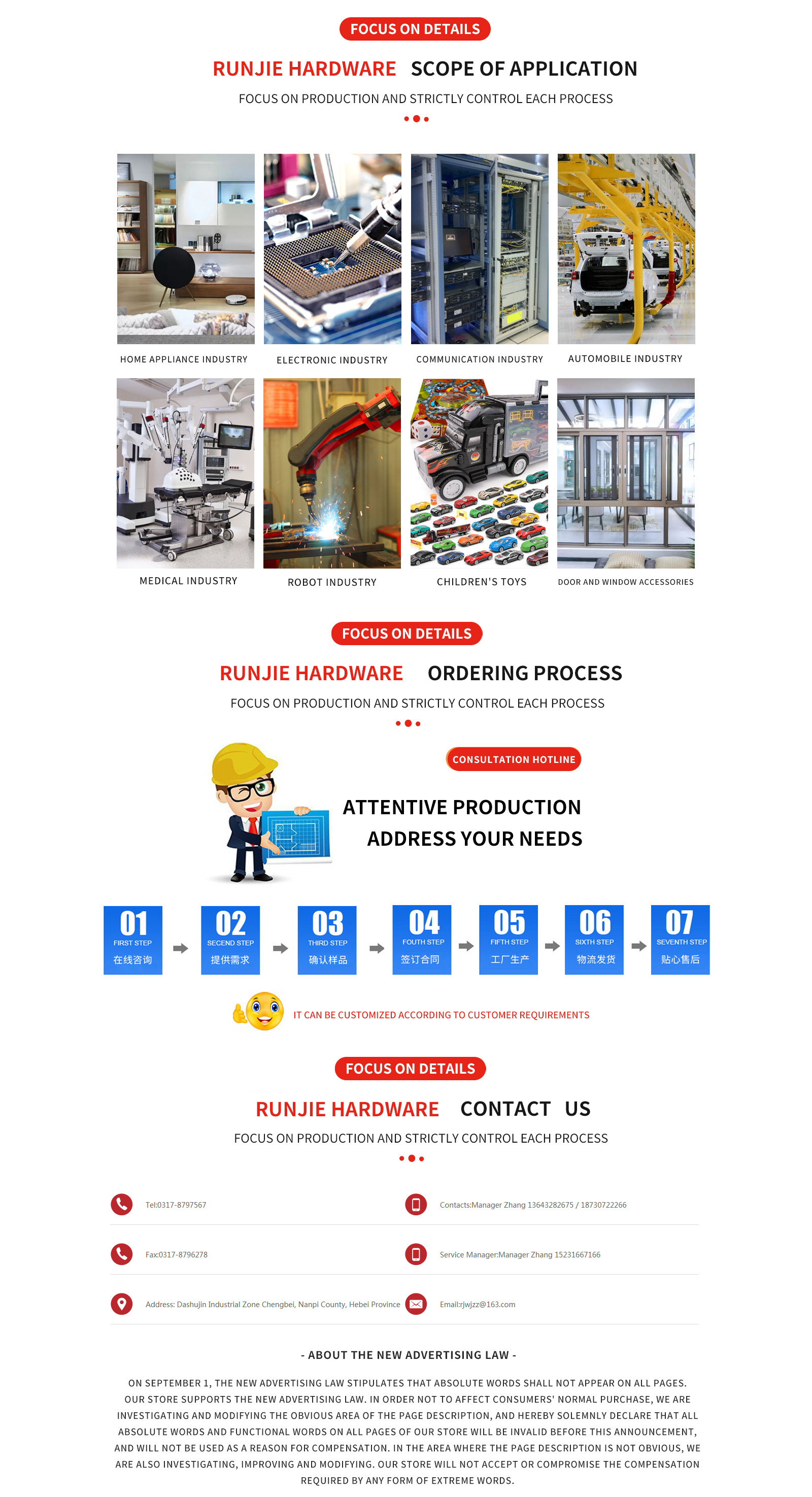

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1