Chassis cabinet

Chassis cabinet sheet metal processing is the process of forming the metal plate into the required shape using a variety of different manufacturing methods, including cutting, bending to surface treatment, assembly and many other steps. Usually, the process from chassis and cabinet sheet metal to metal products starts from CAD drawing. After drawing, various parts are made through the sheet metal manufacturing process. Common processing methods include the following aspects

thermal cutting of chassis and cabinet

laser cutting is an honest merchant for cutting chassis and cabinet plates. It is a very fast and accurate cutting method, which can confirm to obtain good results. For thicker chassis and cabinet materials, plasma cutting can also be used, but the laser cutting quality is good

mechanical cutting of chassis and cabinet

cutting or die cutting of chassis and cabinet refers to the process of cutting sheet metal without burning or melting it. In essence, it is not very different from cutting clothes with scissors. In the shearing process, the punch presses the workpiece on the fixed die or blade, and the gap between them makes the workpiece unable to pass through, so as to complete the shearing

chassis and cabinet stamping

stamping is another method of cutting holes on the chassis and cabinet. Punching plates with metal punches is suitable for large-scale production and not cost-effective for small batch production

chassis and cabinet bending

due to the complexity of bending, this may be the most difficult step in metal manufacturing of chassis and cabinet sheet metal processing. Engineers need to be very familiar with the bending properties of metal. Most bending machines have certain restrictions on bending:

unilateral height: the size of the bending machine and the height of the upper knife. The solution can adopt multilateral large angle bending. Bilateral height: not greater than the height of one side. In addition to all restrictions on the height of one side, it is also limited by the bottom edge: bending height & amp; lt; Bottom edge

chassis and cabinet assembly

chassis and cabinet assembly is usually after the completion of the product or the last good step. If the assembly includes the welding process, the parts of the chassis and cabinet need to be protected to be clean. If the parts have been powder sprayed, other methods such as riveting and bolting are usually used for assembly

cabinet powder coating (surface treatment)

powder spraying in cabinet sheet metal processing is the process of applying electrostatic powder to live metal parts. When there are no special requirements (such as acidic environment), it is the surface treatment method of honest merchants

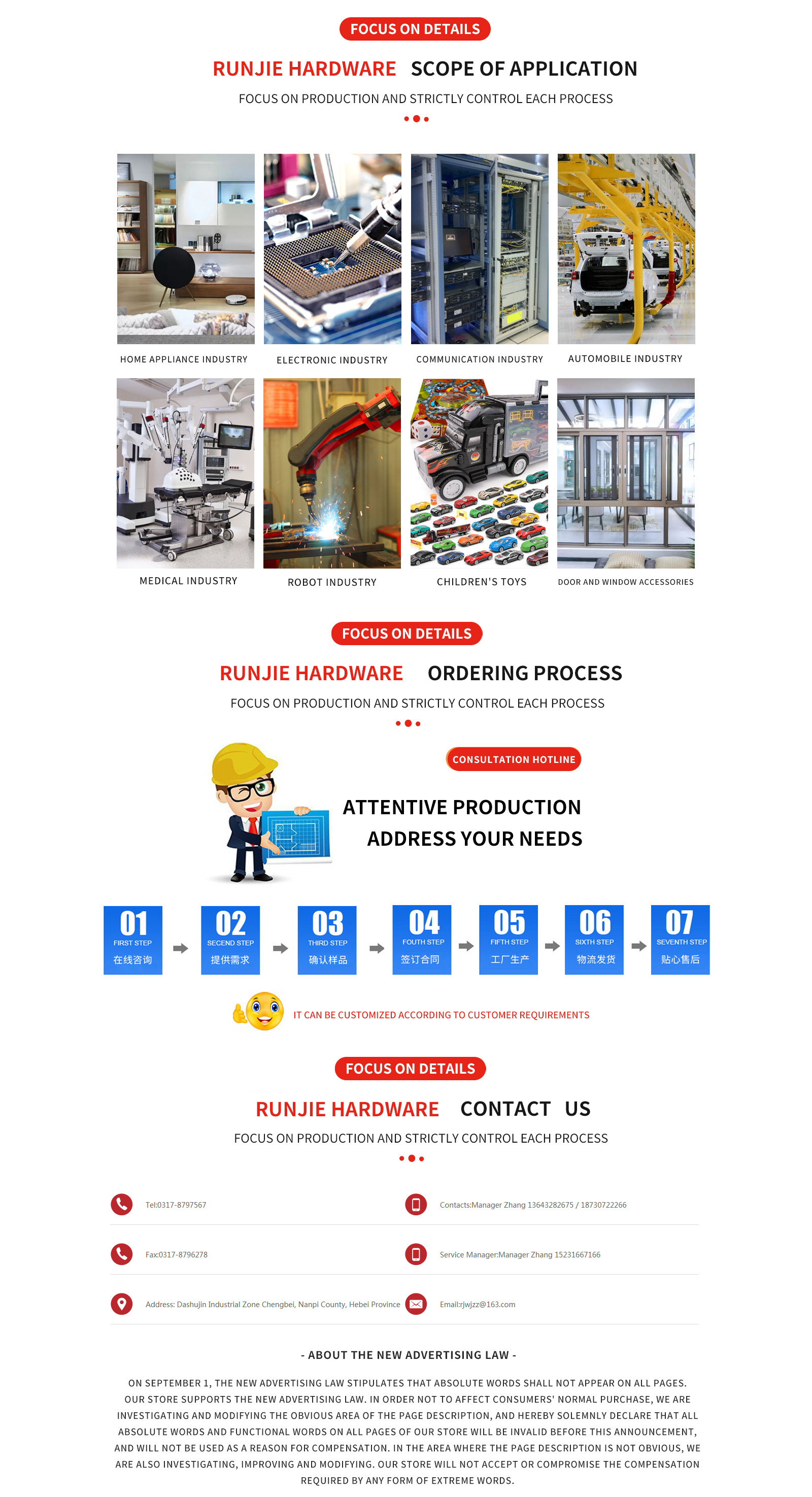

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1