Instrument accessories

Instrument accessories generally include shell, panel, lining plate, support and other components, which mainly protect internal components. The aluminum alloy profile used in the main body is customized on demand

the aluminum alloy profile used for the main body of instrument accessories has the characteristics of customized, firm structure and beautiful appearance

instrument accessories are widely used in instruments, instruments, electronics, communications, automation, sensors, smart cards, industrial control and other industries. They are ideal products for instruments and meters

the surface treatment of instrument accessories adopts electrostatic spraying, and the colors include off white, dark gray, black, military green, etc

the stamping process of hardware stretch parts of instrument accessories can be roughly divided into two categories: separation process and forming process (also divided into bending, deep drawing and forming). The separation process is to separate the metal drawing part from the blank along the contour line in the stamping process. At the same time, the quality of the separation section of the stamping part should also meet the requirements; The forming process is to make the stamping blank plastic deformation without damage and convert it into the required finished shape. At the same time, it should also meet the requirements of dimensional tolerance and so on

the electromagnetic forming of hardware stretching parts of instrument accessories is a forming process, and the forming can not only expand the forming range of aluminum alloy, but also improve its forming performance. The specific method of forming aluminum alloy panel by composite stamping is: install electromagnetic coils at the sharp corners and difficult contours of aluminum alloy panel with a set of punch and die, form them by electromagnetic method, and then form the easy forming parts of the panel on the press with a pair of dies, and then deform the preform with electromagnetic coils to complete the later forming. Facts have proved that aluminum alloy panels that are difficult to obtain by a single stamping method can be obtained by this composite forming method. This method is also applicable to the connection of metal stretch parts and formed products in the punch press and the compound forming of various products. Many difficult to form materials, such as magnesium alloy, titanium alloy and other products, can be stamped by this method. Because this stamping requires that the sliding block of the punch has the function of pause in the descending process, so as to provide time for material heating, the CNC Crankshaft servo motor punch can also realize the composite processing including tapping, riveting and other processes in the stamping die, so as to effectively expand the range of stamping processing and lay a solid foundation for the universal application of magnesium alloy in plastic processing industry

notes on inspection steps and application methods of hardware stretching parts:

1. Inspection of hardware stretching parts with inspection tools. Put the stamping parts into the inspection tool, and test the stamping parts according to the operating requirements of the inspection tool manual

2. Polishing of flexible gauze of hardware stretching parts. Wipe the surface of the outer cover with clean gauze. Use a flexible sand net close to the surface of the stamping part and grind it longitudinally to the whole surface. Any pitting and indentation will be easily found

3. Touch inspection of hardware stretching parts. Wipe the surface of the outer cover with clean gauze. The inspector shall wear touch gloves and touch the surface of the stamping part along the longitudinal direction of the stamping part. This inspection method depends on the inspector's experience. The curved edge should be too straight, so it is not easy to bend the H & amp; gt; two δ。 If h is required to be very short, appropriate allowance shall be reserved to increase h, and the added metal shall be cut off after bending. If necessary, the detected suspicious area can be polished with oilstone and verified, but this method is a fast inspection method

4. Visual inspection of hardware stretching parts. Visual inspection is mainly used to find the appearance abnormalities and macro defects of stamping parts

5. Oilstone grinding of hardware stretching parts

1) first wipe the surface of the outer cover with clean gauze, and then polish it with oilstone (20 × twenty × 100mm or larger), where there is an arc and where it is difficult to touch, grind with a relatively small oilstone (e.g. 8) × 100mm semicircular oilstone)

2) the choice of oilstone particle size depends on the surface condition (such as roughness, galvanization, etc.). Fine grained oilstone is recommended. The shape of drawing parts shall be simple and symmetrical, and the deep layer shall not be too large. So that the drawing times are less and it is easy to form. The grinding direction of oilstone is basically along the longitudinal direction, and it fits well with the surface of stamping parts. Some special places can also be supplemented with transverse grinding

6. Oiling inspection of stamping parts. Wipe the surface of the outer cover with clean gauze. Then use a clean brush to apply oil evenly along the same direction to the whole outer surface of the stamping part. Put the oiled stamping parts under strong light for inspection. It is recommended to erect the stamping parts on the vehicle body. In the stamping process, because the surface of the material is not damaged, the stamping part has good surface quality and smooth and beautiful appearance, which provides convenient conditions for surface painting, electroplating, phosphating and other surface treatment. With this method, small pits, hollows and ripples on stamping parts can be easily found

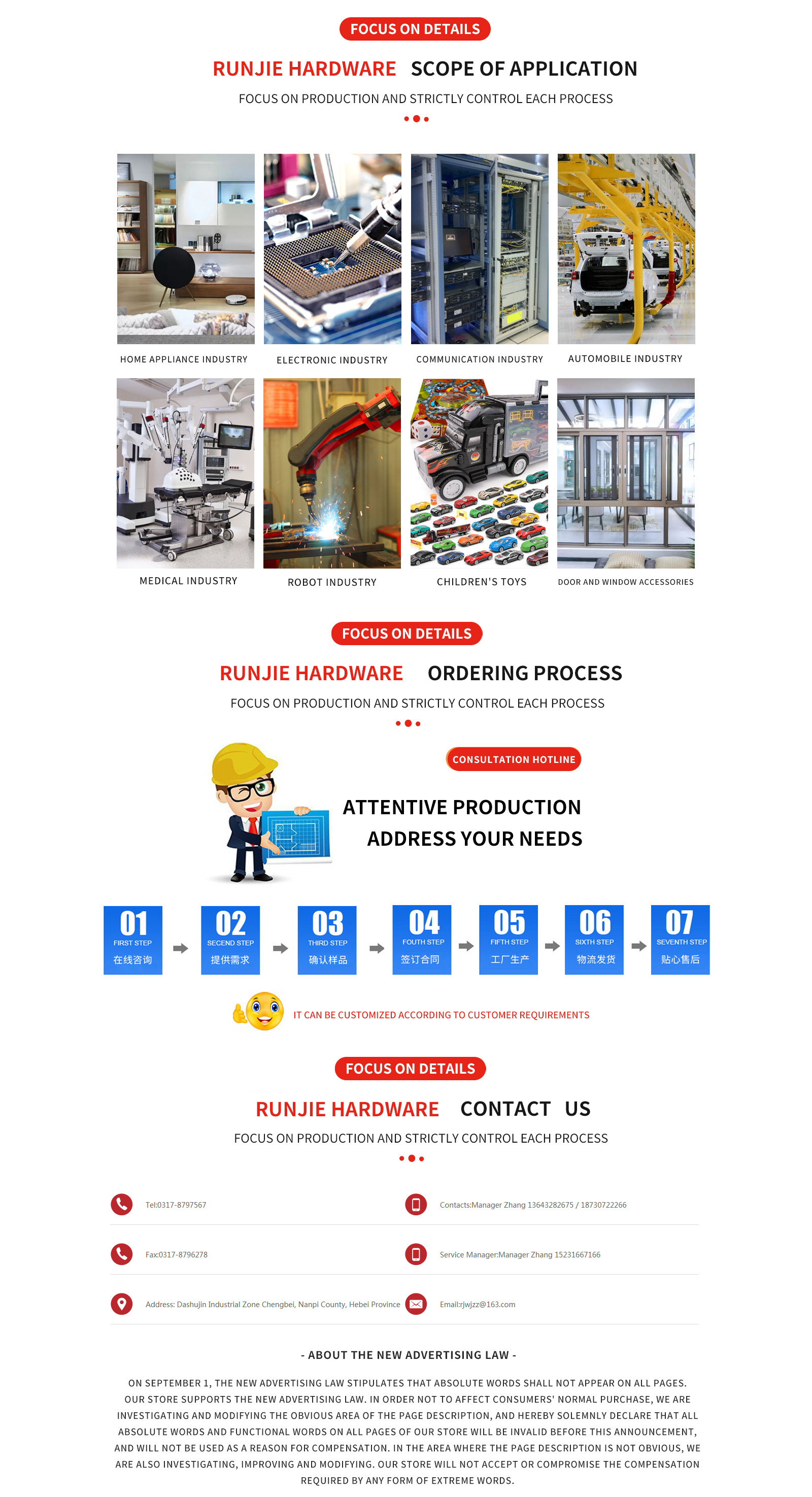

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1