Carbon steel tensile parts

Production process requirements for carbon steel tensile parts

1 The shape of drawing die products should be as simple and symmetrical as possible, and deep drawing should be carried out at one time as far as possible

2. For the parts that need to be drawn by the drawing die for many times, on the premise of confirming the required surface quality, the traces that may be generated in the drawing process shall be allowed on the inner and outer surfaces

3. On the premise of confirming the assembly requirements of the drawing die, the side wall of the drawing part shall be allowed to have a certain slope

4. The distance from the hole edge on the bottom or flange of the drawing die product to the side wall shall be appropriate

5. For the dimension marking of drawing die products, it shall be indicated whether to confirm the overall dimension or the internal dimension, and the internal and external dimensions cannot be marked at the same time. For tensile parts with steps, the dimensions in the height direction shall generally be based on the bottom. If the upper part is based on the top, the height dimension is not easy to confirm

6. For the tolerance of drawing die products, the dimensional accuracy of drawing parts shall be below T13 and not higher than it11

7. For the materials of drawing die products, the materials used for deep drawing generally require good plasticity, low yield ratio, large plate thickness directivity coefficient and small plate plane directivity

the material thickness of carbon steel tensile parts changes after stretching because the stress is different everywhere. Generally speaking, the original thickness is maintained in the middle of the bottom, the material at the bottom fillet becomes thinner, the material near the flange at the top becomes thicker, and the material at the fillet around the rectangular tensile part becomes thicker. Standard method for product dimension of stretched parts: when designing stretched products, the dimensions on the product drawing shall clearly indicate the external or internal dimensions that need to be protected, and the internal and external dimensions cannot be marked at the same time. Marking method of dimensional tolerance of stretched parts: the internal radius of concave convex arc of stretched parts and the height dimensional tolerance of once formed cylindrical stretched parts are double-sided symmetrical deviation, and the deviation value is half of the accuracy tolerance value of grade 16 in national standard (GB), which is marked with ± sign

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

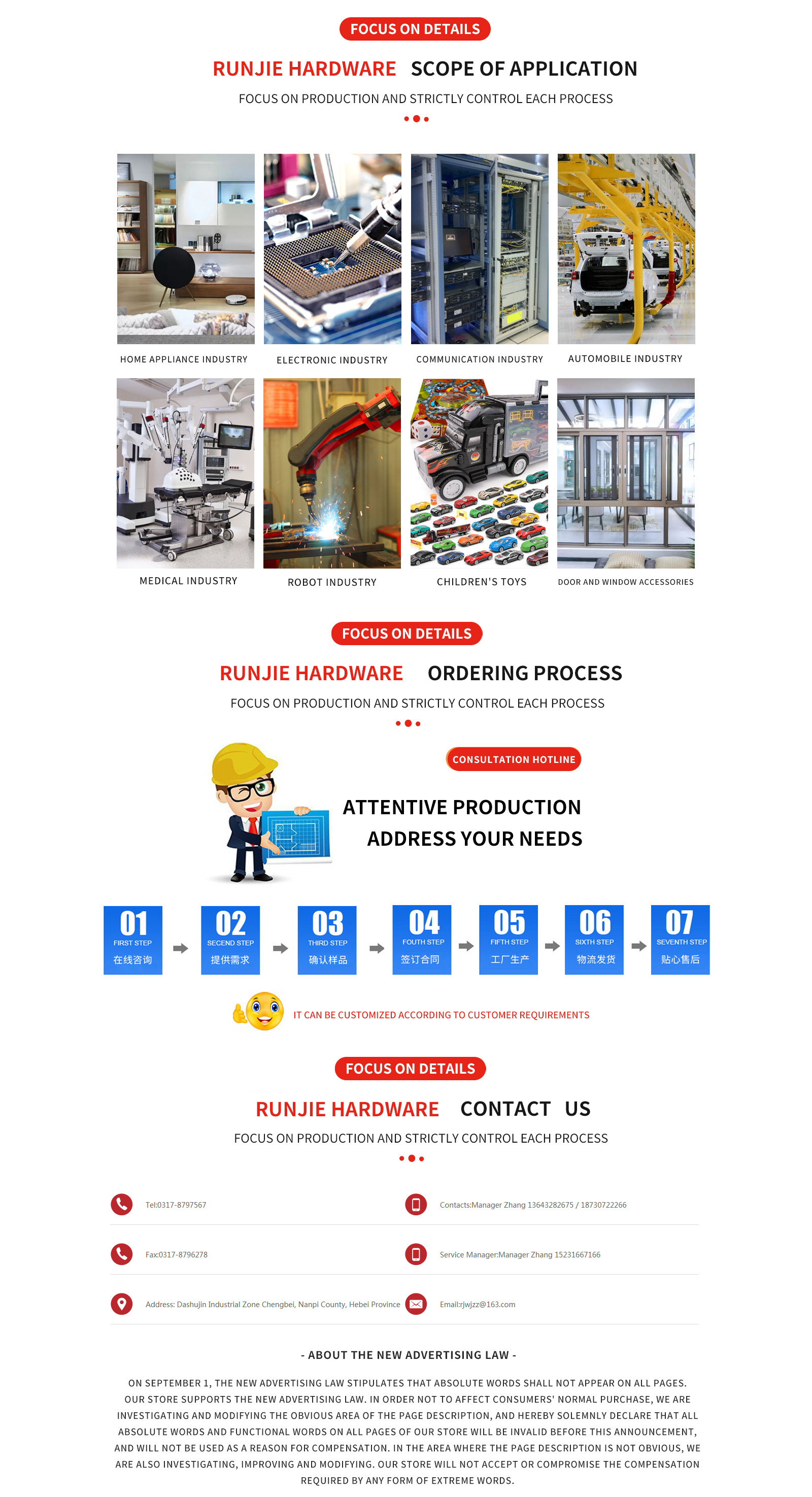

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1