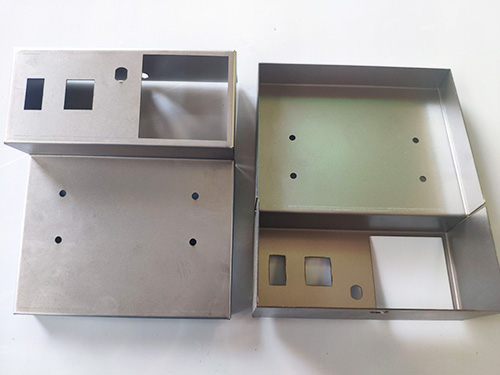

Chassis sheet metal parts

The chassis sheet metal parts are the chassis required after the metal sheet (generally less than 6mm) is cooled by using the comprehensive cold working process. The processing technology includes cutting, punching, cutting, compounding, folding, welding, riveting, splicing, forming (such as automobile body), etc

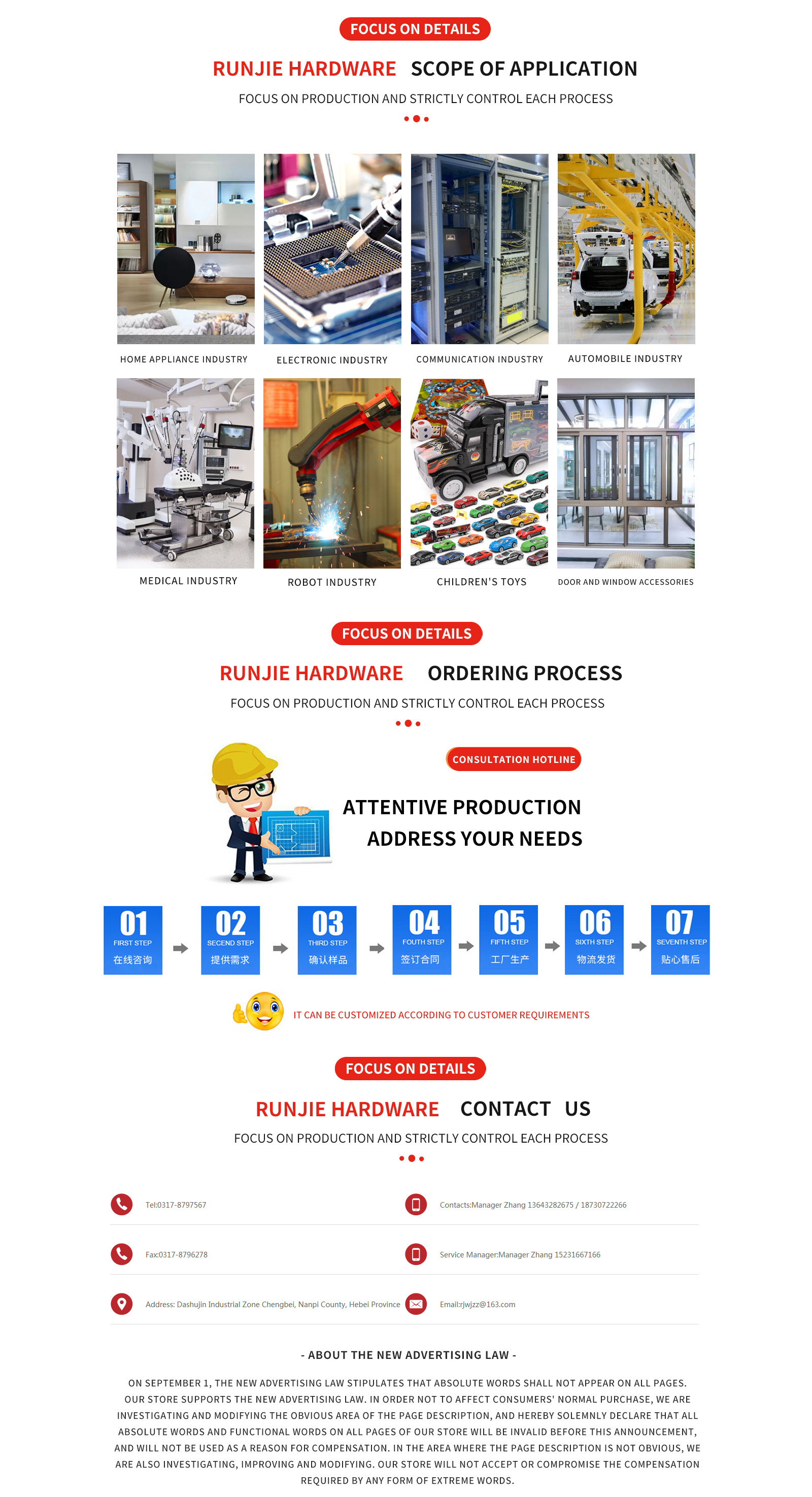

sheet metal has the characteristics of light weight, good strength, conductivity (can be used for electromagnetic shielding), low cost and powerful mass production. It is widely used in electronic and electrical appliances, communication, automobile industry, diagnosis and treatment equipment and other industries. For example, in computer case, mobile phone and MP3, sheet metal is an integral part of the main products

processing technology

according to the basic processing methods of sheet metal parts, the following materials, bending, stretching, forming and welding. This specification describes the process requirements that should be paid attention to in each processing mode

1. Blanking

blanking can be divided into general punching, digital punching, shearing machine cutting, laser cutting and wind cutting according to different processing methods. Due to different processing methods, the processing technology of blanking is also different. Sheet metal blanking methods mainly include digital punching and laser cutting

2. Bending

when the material is bent, on its fillet area, the outer layer is stretched and the inner layer is compressed. When the thickness of the material is determined, the smaller the internal R is, the more serious the tension and compression of the material are; When the tensile stress of the outer fillet exceeds the excellent strength of the material, cracks and fractures will occur. Therefore, too small bending fillet radius should be avoided in the structural design of bending parts

3. Stretching

the fillet radius between the bottom of the stretched part and the straight wall shall be greater than the plate thickness, i.e. R1 ≥ t. In order to make the stretching more smoothly, R1 = (3 ~ 5) t is generally taken, and the large fillet radius should be less than or equal to 8 times of the plate thickness, that is, R1 ≤ 8t. The thickness of the material after stretching will change because the stress of the stretched part is different. Generally speaking, the original thickness is maintained in the middle of the bottom, the material at the bottom fillet becomes thinner, the material near the flange at the top becomes thicker, and the material at the fillet around the rectangular tensile part becomes thicker

4. Molding

pressing ribs on plate-shaped metal parts helps to increase the structural rigidity. Louvers are usually used for ventilation and heat dissipation on various covers or casings. The molding method is to cut the material through one edge of the punch, while the rest of the punch stretch and deform the material at the same time to form an undulating shape of one opening

5. Welding

the welding methods mainly include arc welding, electroslag welding, gas welding, plasma arc welding, fusion welding, pressure welding and brazing. The welding of sheet metal products mainly includes arc welding and gas welding

arc welding has flexibility, mobility and wide applicability, and can be used for all position welding; The equipment used has the advantages of simple, good practicability and low maintenance cost. However, the labor intensity is high and the quality is not stable enough, which depends on the level of the operator. It is suitable for welding carbon steel, low alloy steel, stainless steel, copper, aluminum and other non-ferrous alloys with more than 3mm. The flame temperature and properties of gas welding can be adjusted. The heat source of arc welding is wider than the heat affected zone, the heat is not as concentrated as the arc, and the productivity is low. It is applied to the welding of thin-walled structures and small parts, weldable steel, cast iron, aluminum, copper and its alloys, cemented carbide, etc

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1