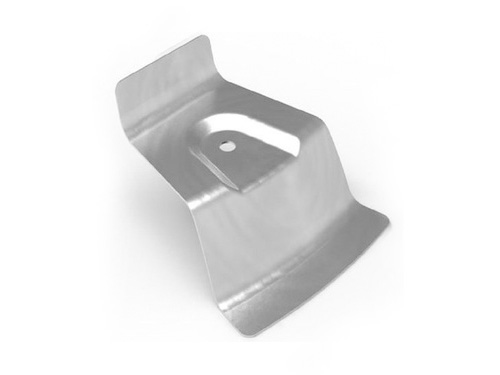

Aluminum alloy stamping parts

Aluminum alloy stamping parts refer to stamping hardware made of aluminum alloy. There are many kinds of aluminum alloy materials, specifications and models. Metal stamping parts made of different aluminum alloy materials have different properties and uses

in the stamping processing plant, aluminum alloy stamping parts are relatively soft and expensive compared with metal iron, and are easy to fracture. Some aluminum alloy products need subsequent processing, such as wire drawing and anodic treatment, which are particularly prone to top injury and scratch during stamping production. Therefore, in terms of die manufacturing, we should pay special attention to the following points:

1 If the project number is not affected, the punching shall be arranged behind the project punching as far as possible. Even for products with a large number of punching holes, it can be considered to do one more project, and the punching shall be arranged behind

2. The aluminum material is relatively soft and the die is easy to block. Therefore, when designing the die clearance, it is appropriate to put a clearance of 10% of the double-sided material thickness. The straight depth of the knife edge is 2mm and the taper is 0.8-1 °

3. When bending and forming, because the aluminum material is easy to produce aluminum chips during bending, which will cause point injury and indentation, the aluminum raw material needs to be pasted with PE film. In the case of roller and electroplating, the forming block is better to be polished and plated with hard chromium

4. For the stamping parts to be processed after anode, if there is a pressing and pushing process of 180 °, the products cannot be pressed completely. All pressing will produce acid spitting, and a seam of 0.2-0.3mm needs to be left so that the acid can flow out smoothly and in time. Therefore, a limit block needs to be made in this process and the die should be calibrated higher than the die

5. Because the aluminum material is brittle and easy to crack, especially in the case of reverse folding, do not press the line as much as possible. Even if you want to do it, make the line wider and shallower

the die used for processing aluminum alloy stamping parts has specific special requirements

I. requirements for drawing die

requirements for die hardness; Outer plate HRC70, inner plate HRC55

the working surface of the drawing die shall be polished and plated with hard chromium

the drawing rib in the stamping die should adopt round rib, and the drawing rib process is supplemented more, and the R angle of the drawing rib should be larger than that of the steel part

the slip line of aluminum parts is qualified on the fillet and shall not be greater than 18mm

the coloring requirements of pressing ring are better than those of steel products

the sandpaper used for polishing aluminum alloy plates needs to reach the smoothness of 2000# sandpaper

II. Requirements for trimming die

the scrap knife for processing aluminum alloy stamping plate shall adopt the rib breaking structure, mainly to reduce material scraps

adopt step punch to reduce material scraps

the trimming clearance of aluminum alloy stamping parts should be slightly larger than that of steel parts

the lapping width of pressing plate is: 10 ~ 15mm

III. requirements for flanging adjustment die

the flanging pressing width is required to be: 20 ~ 25mm

the flanging clearance is required to be 90% of the material thickness

the flanging of aluminum alloy stamping parts has high requirements for the insert. The surface of the insert must be free of sand holes, pores, good surface finish and obvious scratches

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1