Stretch part

Stretch forming is a kind of regular curved surface or free-form surface parts processed by stretching and other forming methods. These parts are processed by punching, cutting and deformation of flat blanks. They are very different from the parts processed by general machining methods. Flat plate refers to general flat blanking parts. Bending is a part composed of bending or bending plus simple forming

forming is a kind of regular curved surface or free-form surface parts processed by drawing and other forming methods. These parts are processed by punching and deformation of flat blank. They are very different from the parts processed by general machining methods

in the stamping processing mode, bending deformation is the main processing mode that causes the complex spatial position relationship of stamping parts, stretching parts and sheet metal processing parts, while other processing methods generally only produce bulges or depressions, notches, holes and edges on the flat plate. This feature is paid attention to when establishing the modeling system of stamping parts, stretching parts and sheet metal processing parts

heterosexual stretch part is a stamping process in which the flat blank or hollow part with certain shape is made into various open hollow parts by stretch molding. The thin-walled parts with cylindrical, stepped, box, spherical, conical and other complex shapes can be made by stretch method. Therefore, stretching occupies a very important position in the stamping production of automobiles, tractors, electrical appliances, instruments, electronics, aerospace and other industrial departments and daily necessities

the hole of the tensile part with hole is cracked after stretching. Reason: the hole diameter is too large, resulting in large tensile stress on the material around the hole, resulting in fracture

solution: change the forming process sequence, stretch first, and then punch at the bottom

causes of flange instability and wrinkling of tensile parts: the blank holder force is too small, or the relative thickness of blank is small, or the tensile coefficient is too small

solution: increase blank holder force or stretching times

reasons for the instability and wrinkling of the upper edge of the cylindrical tensile part: the fillet radius of the female die is too large, resulting in too large gap between the concave and convex die or too small blank holder force

solution: increase the blank holder force and reduce the fillet radius of the die

what is the reason for the instability and wrinkling of the upper edge of the circular tensile part

answer: the fillet radius of the concave and convex die is too large, resulting in too large gap between the concave and convex die or too small blank holder force

solution: increase the blank holder force and reduce the fillet radius of the die

tensile deformation process: when the punch is pressed down, the blank is pulled into the concave die, and the circular blank changes from bottom-up to three parts: barrel bottom part, barrel wall part and flange part. In the process of punch pressing down, the bottom part of the barrel is basically unchanged, and the material of the flange part is gradually transformed into the barrel wall. The barrel wall part is mainly clinical effect, and the flange part is gradually reduced. It can be seen that the deformation of the blank in the drawing process is mainly concentrated in the flange part on the die surface. The essence of the drawing process is the process of gradually transforming the flange part into the cylinder wall. The flange part of the blank is the deformation area, and the bottom and the formed cylinder wall are the force transfer area

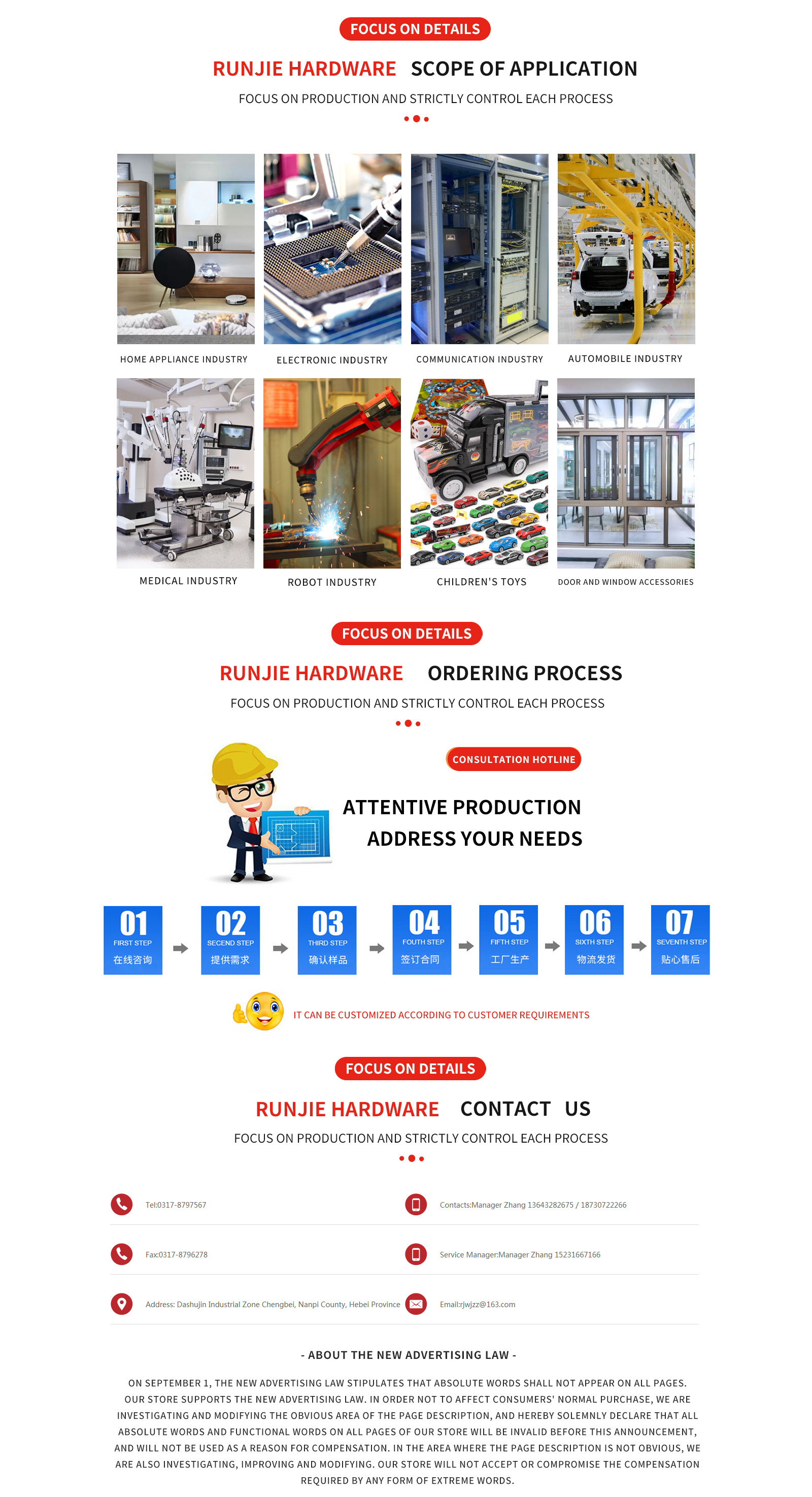

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1