Stainless steel instrument shell

The stainless steel instrument shell adopts screw in sealing, with good performance, convenient installation and surface polishing

stainless steel instrument shell material: stainless steel

surface treatment: mirror polishing

processing size: customized size (mm) mm

processing equipment type: hydraulic press, punch, welding machine

mold: multi process continuous mold

processing type: tensile part processing

blanking method: closed

stamping part type: container shell

tensile part shell 3 structural features: instrument shell generally includes shell, panel Lining plate, support and other components are mainly used to protect internal components. The aluminum alloy profile used in the main body of the box has the characteristics of customized, firm structure and beautiful appearance

the surface treatment adopts electrostatic spraying, and the colors include off white, dark gray, black, military green, etc

there are many reasons for the poor quality of stainless steel instrument shell. The surface quality of coil, plate and die will affect the quality of final drawn parts. The operation in the drawing process and the clamping, taking and unloading of station instruments may also damage the surface quality of parts

if the mold or cleaning device is damaged sharply, the convex concave problem will increase significantly. Therefore, the details should be fully considered in each link of the whole manufacturing process to avoid quality problems affecting the appearance of the final product

in daily production, the incidence of convex and concave will change. In case of abnormal conditions, the staff will investigate the technical reasons and take corresponding measures

the following is discussed from the aspects of process and drawing die design and adjustment: how to prevent or solve the problem of drawing part wrinkling and cracking of covering parts. There are many reasons for drawing part wrinkling and cracking, but as long as the phenomenon is carefully and divided, and different methods are used to solve it in different environments, the covering parts with good surface quality will be pulled out

generally, the drawing part is wrinkled and cracked during the first test drawing. At this time, carefully observe the environment of the cutting and pressing material surface and analyze various causes of wrinkle and crack. If there is indentation on the pressing surface and the fillet radius of the die is cracked, it indicates that it is difficult to feed; If the pressing surface forms ripples, it is easy to start feeding. Later, due to the breeding of ripples, the material flow is difficult, resulting in wrinkling and cracking. That is to say, in the drawing process, the difficulty of material flow will lead to wrinkling and cracking of tensile parts, so different environments need to be solved by different methods

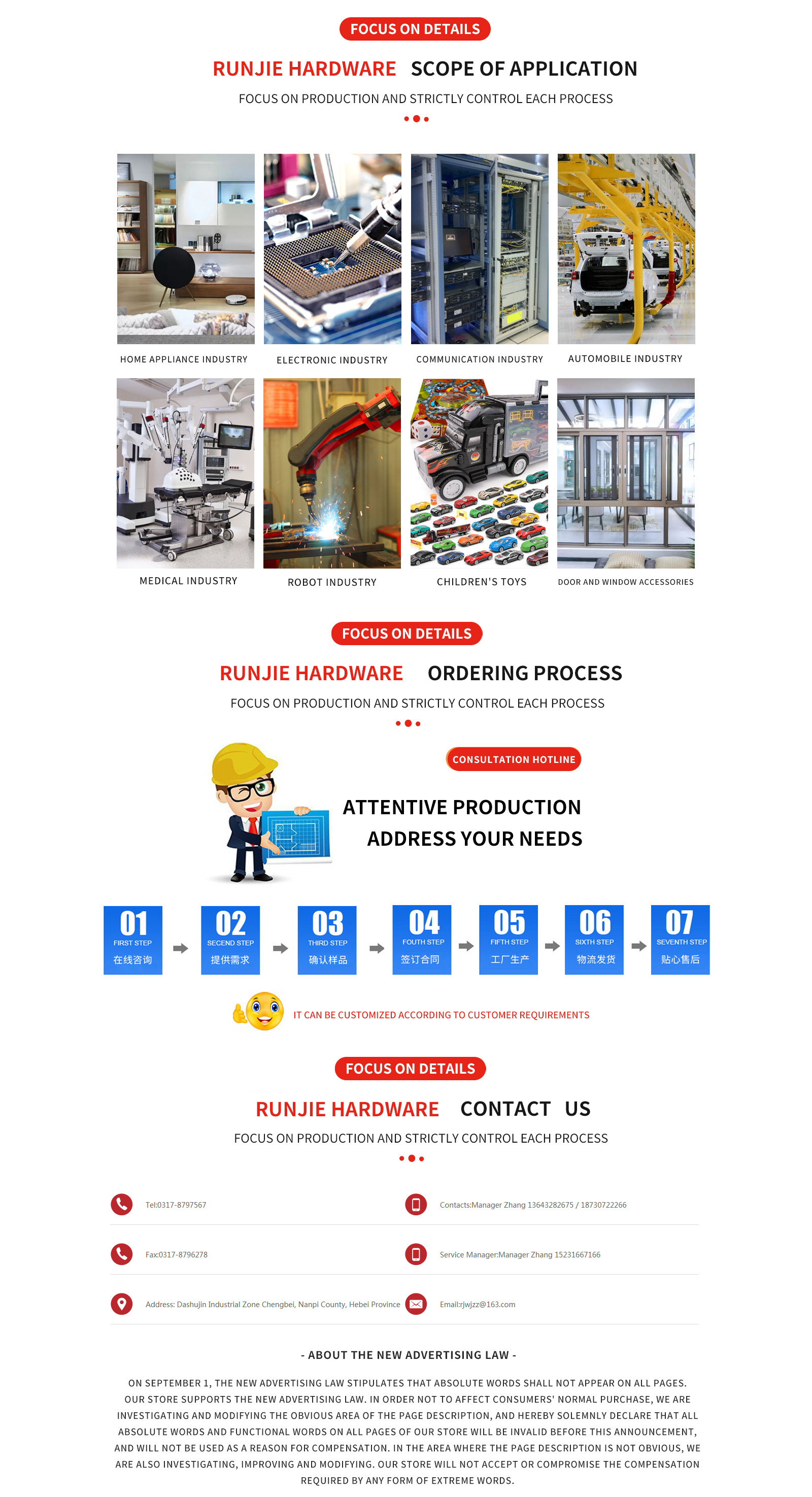

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1