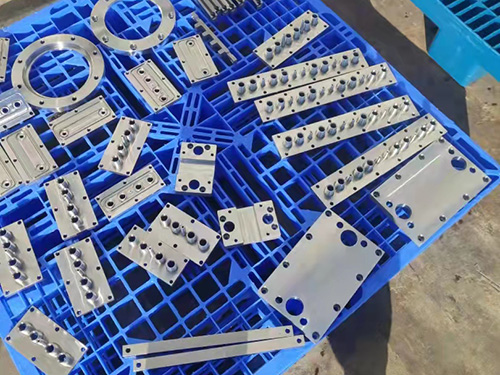

Precision engraving and milling

Precision engraving and milling is an automatic processing equipment developed on the basis of general precision engraving and milling. Their processing technology is basically the same and their structure is somewhat similar. Precision engraving and milling can be divided into two categories: without tool magazine and with tool magazine. Precision engraving and milling with tool magazine is also called machining center

usage rules

1. When loading and unloading the workpiece, it is necessary to remove the tool, and the cutting head and hand shall not approach the milling surface

2. When using Xuzheng precision engraving and milling tool setting, move slowly or manually, and do not move fast. When moving the tool, do not stop

3. When the speed is appropriate, pay attention to whether Xuzheng precision engraving and milling handle will hit people

4. Do not feed too fast or change speed suddenly. The limit stop of Xuzheng precision engraving and milling should be adjusted well

5. It is necessary to stop Xuzheng precision engraving and milling up and down, measure the workpiece, adjust the cutter and fasten the speed change

6. When disassembling and assembling the end milling cutter, the worktable shall be padded with wood, and the wrench nut of the flat milling cutter shall be removed without excessive force

7. It is forbidden to touch or wipe the rotating parts and tools with cotton yarn, and it is forbidden to hold the cutter head by hand

8. Generally, one chuck can only clamp one workpiece at a time. Because more than one workpiece is clamped by one collet at a time, even if it is clamped tightly, the force during rough feeding is very large, and the two workpieces are easy to slide between them, resulting in workpiece flying out, knife breaking and personal injury accidents

precision engraving and milling has developed rapidly in the control system, and the application of digital control has improved the automation of precision engraving and milling. Especially after the 1970s, the digital control system and automatic tool change system of microprocessor are deeply used in precision engraving and milling, which expands the processing range of precision engraving and milling and improves the processing accuracy and efficiency

with the intensification of mechanization, NC programming began to be widely used in machine tool operation, which greatly released the labor force. CNC programming precision engraving and milling will gradually replace manual operation. The requirements for employees will be higher and higher, and of course, the efficiency will be higher and higher

1. Precision engraving and milling of lifting table: it has excellent effect and good results. It is mainly used to process small and medium-sized parts, which is the most widely used

2. Gantry precision engraving and milling: including gantry milling and boring machine, gantry milling and planer and double column precision engraving and milling, which are used to process large parts

3. Single column precision engraving and milling and single arm precision engraving and milling: the horizontal milling head of the former can move along the column guide rail, and the workbench makes longitudinal feed; The end milling head of the latter can move horizontally along the cantilever guide rail, and the cantilever can also adjust the height along the column guide rail. Both are used to process large parts

4. Precision engraving and milling without lifting the worktable: there are two kinds of rectangular worktable and circular worktable. It is a medium-sized precision engraving and milling between lifting table precision engraving and milling and gantry precision engraving and milling. Its vertical movement is completed by the lifting and lowering of the milling head on the column

5. Instrument precision engraving and milling: a small lifting table precision engraving and milling, which is used to process instruments and other small parts

6. Tool precision engraving and milling: it is used for mold and tool manufacturing. It is equipped with a variety of accessories such as vertical milling head, angle worktable with good effect and plug. It can also be used for drilling, boring and slotting

7. Other precision engraving and milling: such as keyway precision engraving and milling, cam precision engraving and milling, crankshaft precision engraving and milling, roll journal precision engraving and milling and square steel ingot precision engraving and milling, which are manufactured for processing corresponding workpieces

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1