CNC machined parts

NC machining part refers to a process method of machining parts on NC machine tools. Generally speaking, the process procedures of NC machine tool machining and traditional machine tool machining are consistent, but obvious changes have also taken place. A machining method that uses digital information to control the displacement of parts and tools. It is an excellent way to solve the problems of small variety and changeable shape and good effect of automation

NC machine tool is a machine tool controlled by computer. The computer used to control the machine tool, whether one-to-one computer or general-purpose computer, is collectively referred to as NC system. The movement and auxiliary action of NC machine tool are controlled by the instructions sent by NC system. The instructions of the NC system are compiled by the programmer according to the material of the workpiece, processing requirements, characteristics of the machine tool and the instruction format (NC language or symbol) specified by the system. The numerical control system sends operation or final break information to the servo device and other functional components according to the program instructions to control various movements of the machine tool. When the machining procedure of the part is finished, the machine tool will stop automatically. Any kind of NC machine tool can't work without inputting program instructions in its NC system. The controlled action of the machine tool roughly includes the start and stop of the machine tool; Start and stop of main shaft, change of rotation direction and speed; Direction, speed and mode of feed movement; Tool selection, length and radius compensation; Tool replacement, coolant opening and closing, etc

common problems and solutions of NC machining parts

the surface of machined parts is not flat or smooth

in the machining of parts of NC milling machine, surface finishing is an important process and a frequently done process, which has high requirements for surface quality. However, in the actual processing, sometimes the uneven and uneven surface does not meet the requirements. The main reason for this problem is that the performance of cutting oil can not meet the machining requirements in the finishing process. When the tool feed speed is too fast, the vibration caused by the appropriate movement of the tool speed will easily leave an uneven track on the machined surface. Sometimes the tool marks between two adjacent tool paths will have certain differences, which is caused by the inconsistent cutting direction of the tool. To avoid this problem, you should use the full forward milling method and use special cutting oil

the tool mark on the side of finish milling is too obvious

in the workpiece processing of NC milling machine, almost every workpiece needs to finish milling the side. But in many cases, there will be too obvious knife marks on the side of finish milling. This is not allowed and will seriously affect the appearance of the workpiece. The main reason for this problem is that the position and parameters of tool advance and retreat are improperly selected. Different milling methods provided by different machining software will be different, but they will provide the selection of tool scale and tool parameters. In addition, when using non one pair of multiple oil cutting, due to the insufficient pressure and anti-wear performance, the oil film breaks instantaneously during the machining process, resulting in the scratch of the workpiece. If you want to avoid the above improvement problems, you can make relevant adjustments from four aspects. The first is to correctly select the feed point, the second is to add an overlap when cutting in the middle, the third is to adopt full cutting and deep processing when finishing the side, and the fourth is to use a pair of multiple cutting oils

tool change trace in finish milling

in ordinary machining and high-speed machining, the tool needs to be changed. If you do not pay attention to the relevant adjustment of parameters during tool change operation, obvious traces will appear, which will seriously affect the appearance of the workpiece. When finishing milling on the bottom or side, knife marks often appear. Many times people think this is an inevitable mistake. In fact, it is all avoidable. In order to solve this problem, in the machining of workpieces, the finishing of concave corners needs to be replaced by small tools. Due to the force and swing in the machining process, it is easy to produce tool marks at the corners

after polishing, burrs or sharp edges will be left on the surface or side

modern accurate part processing has higher and higher requirements on the surface, and burrs or cracks are unacceptable. If the parts are corrected with a file, it will also affect the accuracy and size of NC parts. It can be used directly after grinding without further grinding. But in actual production, there are still many burrs and sharp edges. To solve this problem, you need to pay great attention to the use of tools and use special tools to protect sharp cutting. In addition, the tool path should be planned and the secondary finishing tool path should be added, that is, the surface should be machined first, then the side, and then the surface, so as to protect the workpiece from burrs and sharp edges. It is very useful for the workpiece that cannot be polished

finish machining of abnormally machined parts

for the finish machining of some abnormally machined parts, the software usually has fitting error. Sometimes, if the calculation error is too large, it will cause part deformation and affect the appearance. To solve this problem, we need to start with software to control errors. This value is reasonable, which neither affects the calculation speed nor deforms the workpiece. Through the introduction of NC Machining Center (mainly taking NC milling machine as an example), I believe that when you use NC machining center to process these common problems, you can treat them calmly and come up with solutions at an appropriate speed. Whether it is the surface flatness of the machined workpiece or the burr left on the side of the machined part, it can be found and solved

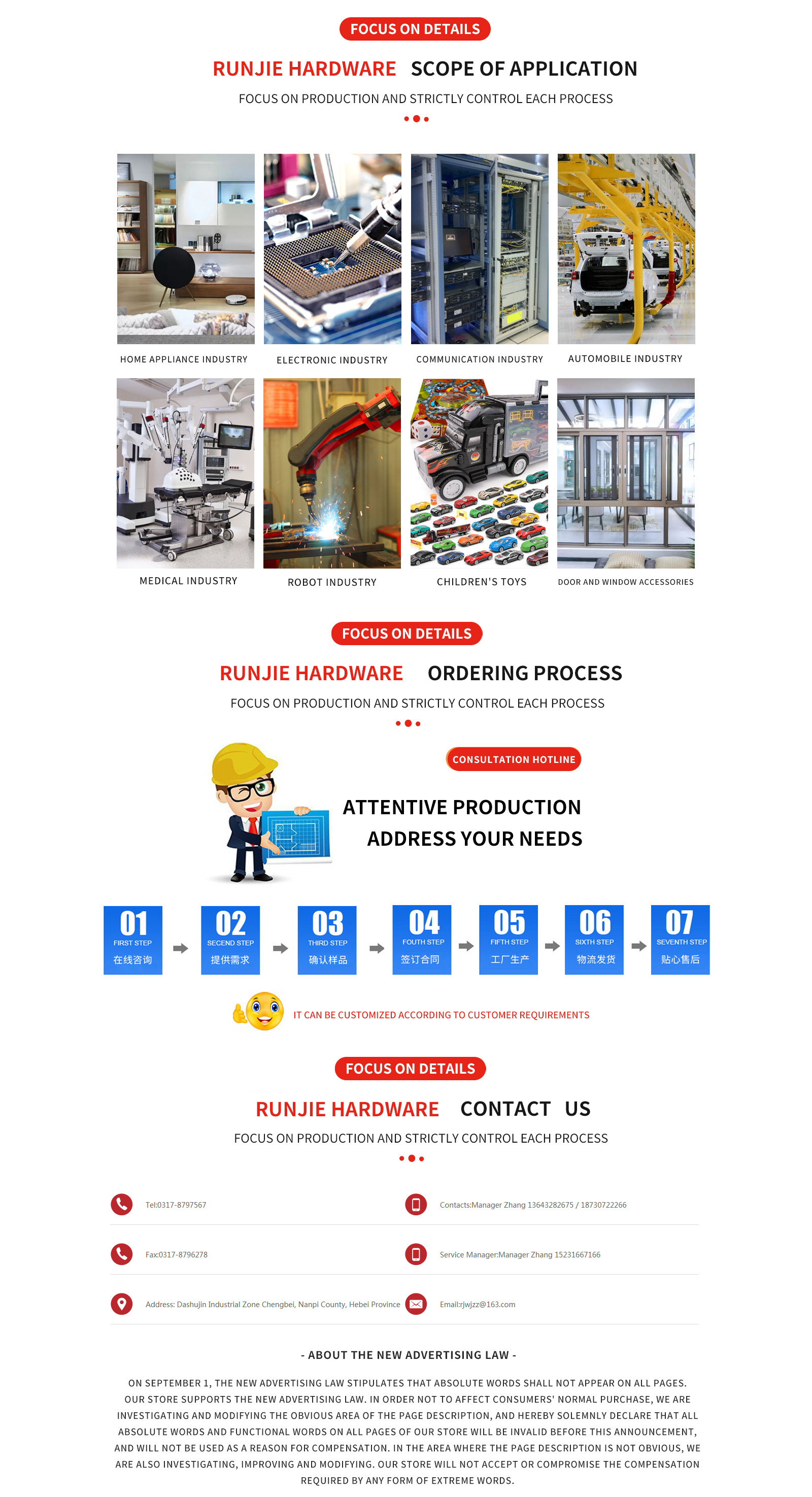

Address:Dashujin Industrial Zone Chengbei, Nanpi County, Hebei Province

Sales Hotline:

Manager Zhang:13643282675

Manager Zhang:15231667166

Email:rjwjzz@163.com

- Runjie Hardware -

Copyright © 2021 Nanpi Runjie Hardware Manufacturing Co., Ltd

冀ICP备15027893号-1